Miele Miele & Cie. KG manufactures household appliances such as vacuum cleaners and washing machines. Many components, including the electric motors for vacuum cleaners, are assembled in series production. In the first step, the rotor, equipped with press-fitted ball bearings, is bonded to the bearing shield. The quality of the adhesive bead on the bearing ring is critical to the final product quality.

aiXbrain shall analyze adhesive beads captured by a camera using artificial intelligence to assess the subsequent stability of the workpiece and provide suggestions for improvement if issues are detected.

The joint goal is to identify quality defects in electric motors as early as possible in the production process and prevent waste of valuable semi-finished products.

As part of the BMBF-funded GeMeKI project, the adhesive dispensing system was upgraded with a line scan camera. Both the camera and the dispenser control send their data to a locally installed Raspberry Pi, which serves as a gateway to the AI.

Training data was generated by manually labeling defect workpieces in Miele’s production line as well as by using a training cell provided by Xenon, which simulates representative defect patterns with workpiece models.

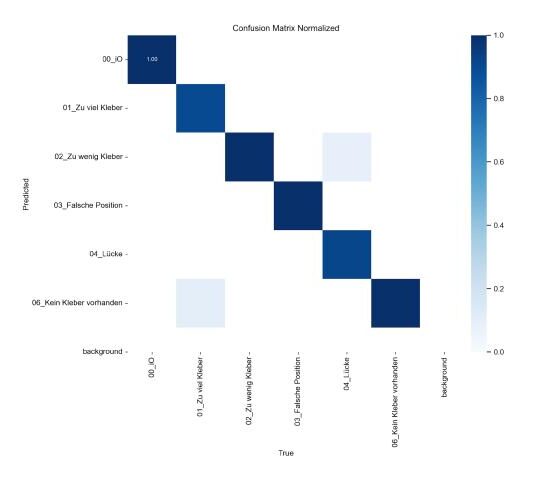

A pre-trained image classification AI model was fine-tuned with the data.

The trained AI classifies good and defective adhesive beads with near 100% accuracy. Identified defect patterns are directly linked to corresponding corrective actions.

The AI system effectively supports workers on the assembly line in inspecting workpiece and process quality, enabling faster and more reliable operations.

New staff can be trained more quickly, while scrap and rework are significantly reduced.

The combination of cost-effective hardware and fine-tuned pre-trained AI models offers an economically attractive alternative to expensive machine vision systems.

aiXbrain offers the used AI component as a Managed Service through its Dataray® AI Framework.

"The AI assistance system enables more effective workflows and gives our employees the ability to intervene early to prevent scrap and reduce costs."

"The AI assistance system enables more effective workflows and gives our employees the ability to intervene early to prevent scrap and reduce costs."